Introduction

|

| The Alfa Laval MultiJet 45 is a rotary jet head tank cleaning machines for use in industrial environments. Built to clean tanks with capacities up to 500 m3 it combines pressure and flow to create high-impact cleaning jets that rotate in a repeatable and reliable 360- degree cleaning pattern |

| The MultiJet 45 minimizes the consumption of water, and cleaning media. Easy to customize to meet customer requirements, it allows companies to spend less time cleaning and more time producing. |

| |

Application

|

| The Alfa Laval MultiJet 45 is designed for the removal of the toughest residues from industrial tanks across a broad range of industries, such as the chemical, pulp and paper, ethanol, starch, oil. |

| |

Benefits

|

- 60% faster cleaning = more time for production

- Saves up to 70% of your cleaning cost

- Eliminates the need for confined space entry for manual tank cleaning

- Allows re-circulation of CIP media with particles in, up to 3 mm particle size

- Robust and durable design

|

| |

Standard Design

|

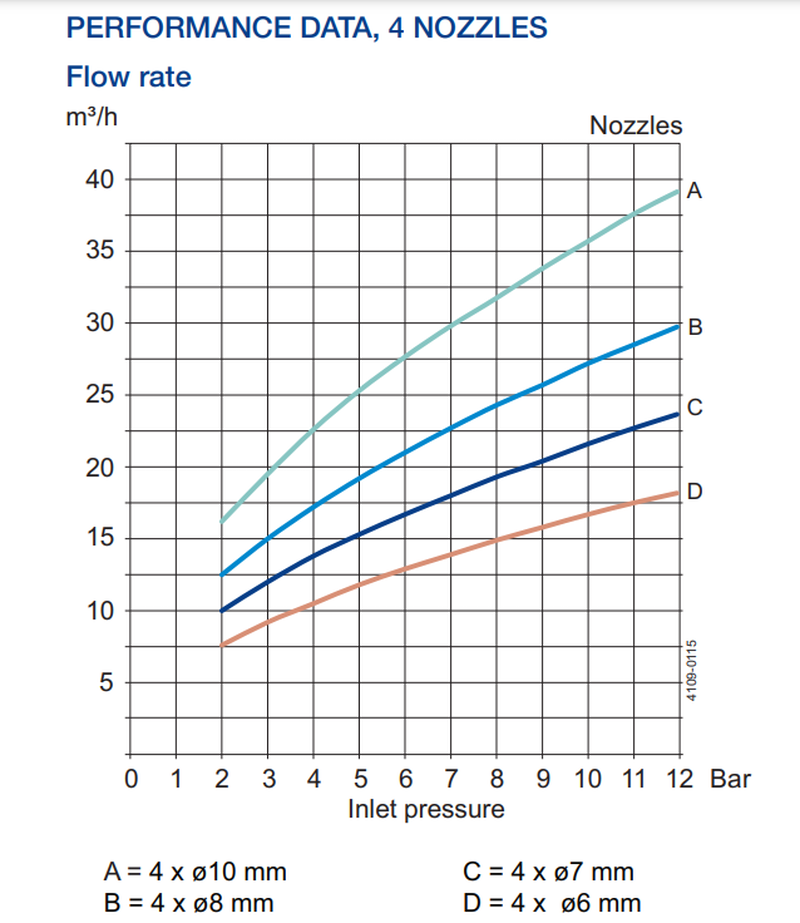

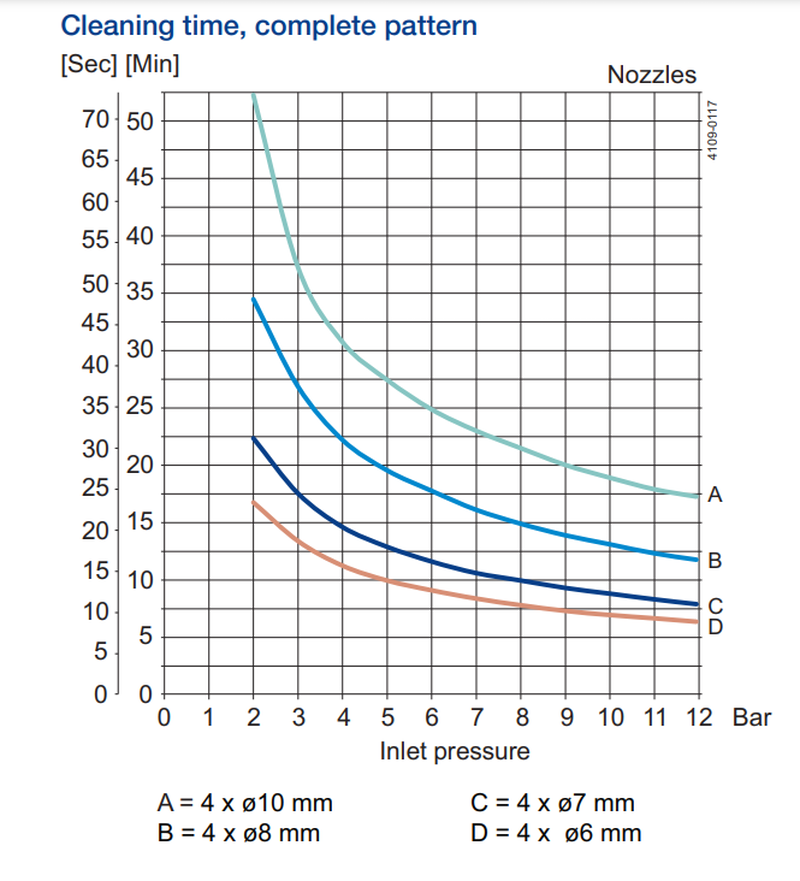

| The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. A 2.1 material certificate and an ATEX certification are available. |

| Alfa Laval offers a wide range of tank cleaning machines suitable for different duties and industries. An alternative that offers performance similar to the Alfa Laval MultiJet 45 is the Alfa Laval GJ 8 for applications that require a small tank inlet opening. |

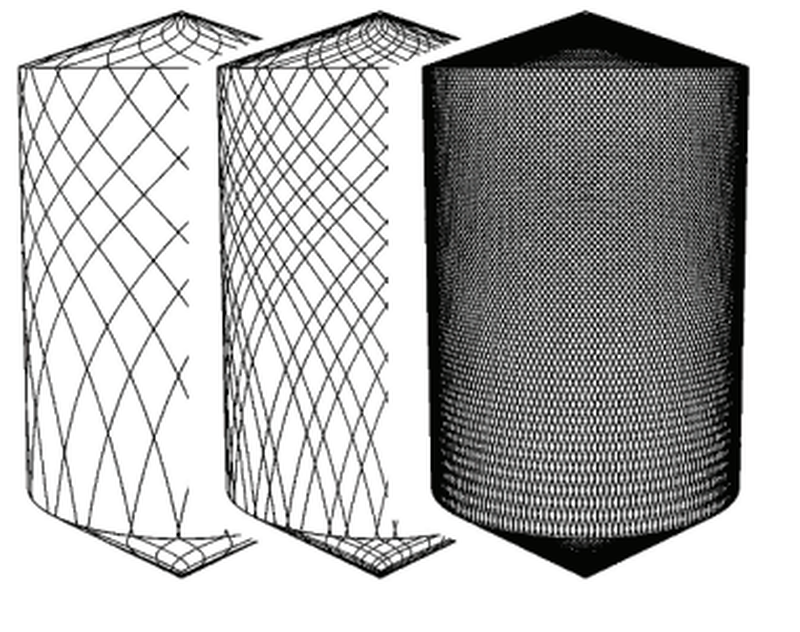

| The above drawings show the cleaning pattern achieved on a cylindrical horizontal vessel. The difference between the first cycle and the full pattern represents the number of additional cycles available to increase the density of the cleaning. |

| |

Working principle

|

| The high-impact jet stream from the Alfa Laval MultiJet 45 rotary jet head covers the entire surface 360° of the tank interior in a successively denser pattern. This achieves a powerful mechanical impact with a low volume of water and cleaning media. |

| The flow of the cleaning fluid makes the nozzles perform a geared rotation around the vertical and horizontal axes. In the first cycle, the nozzles lay out a course pattern on the tank surface. The subsequent cycles gradually make the pattern denser until at full cleaning pattern is reached. |

| Once the full cleaning pattern is reached, the machine will start over again and continue to perform the next full cleaning pattern. |

|

| |

Certificates

|

| 2.1 material certificate and ATEX. |

|

|

|

| |

TECHNICAL DATA

|

| |

| |

|

| Lubricant |

Self-lubricating with the cleaning fluid |

| Max. throw length: |

4 nozzle: 8 - 17 m |

| Impact throw length: |

4 nozzles: 4 - 10 m |

|

| |

| Pressure |

|

| Working pressure: |

4 nozzles: 3 - 12 bar |

| Recommended pressure: |

4 nozzles: 5 - 6.5 bar |

|

| |

PHYSICAL DATA

|

| |

| Materials |

| 316L (UNS S31603), PTFE, PEEK, ETFE, FPM, TFM |

|

| |

| Surface finish |

|

| Exterior finish: |

Mat |

|

| |

| Temperature |

|

| Max. working temperature: |

95°C |

| Max. ambient temperature: |

140°C |

|

| |

| |

|

| Weight: |

4 nozzles: 6.1 kg |

|

| |

| Connections |

|

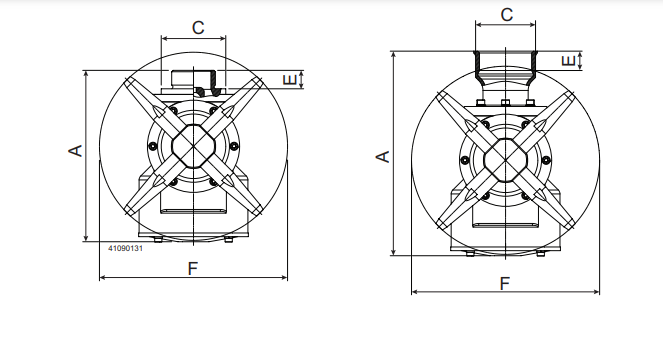

| Standard female thread: |

1½"Rp (BSP) male, 1½" NPT male, adapter connection |

|

| |

Caution

|

| Avoid hydraulic shock, hard and abrasive particles above 3 mm in the cleaning liquid, as this can cause increased wear and/or damage of internal mechanisms. In general, a filter in the supply line is recommended. Do not use for gas evacuation or air dispersion. For steaming we refer to the manual. |

| |

|

|

|

|

|

|

|

Thread (1½” Rp) male or Thread (1½” NPT) male

|

|

|

Female connection, prepared for adapter

|

| |

A |

C |

E |

F |

| mm |

222 |

222 |

21 |

204 |

|

|

|

Qualification Documentation

|

| Documentation specification |

|

| ATEX |

ATEX approved machine for use in explosive atmospheres

Catagory 1 for installation in zone 0/20 in accordance with Directive 2014/34/EU

II 1G Ex h IIC 85 °C ... 175 °C Ga

II 1D Ex h IIIC T85 °C ... T140 °C Da |

|